Company

TKV Thermoform GmbH is a highly efficient, flexible plastics-processing company, manufacturing moulded parts by means of the injection moulding process.

We use the gathered experience in order to be able to offer our present customers all-round services of the product “plastic moulding”. The advanced technical equipment of all our departments as well as our experienced and highly motivated staff ensure that the wishes and specifications of our customers are best possibly implemented.

Our investments in technical equipment for injection moulding, construction and tool making are an expression of our constant efforts to improve our products. They offer us the opportunity to advise our customers optimally and according to the latest state of the art and to implement their wishes.

Quality management

By a high quality standard we secure the competitiveness of our customers. A quality inspection equipped with the latest state of the art enables a constant quality of the plastic parts through constant inspection and evaluation.

Our environmental policy

Since 2009, an environmental management system has been integrated into the existing QM system of TKV Thermoform GmbH.

Our main objectives are to use energy resources and raw materials economically as well as to avoid emissions and uncontrolled release of pollutants into the environment.

Services

Consultation

We help you to obtain the ideal solution and are at your service from the product development up to the finished plastic moulding.

We take care of the plastic-compatible design of the moulding and assist you in the selection of the material, taking the economic and ecological aspects into account.

Our technical services

- Product development

- Decoration of your products by ultrasonic welding, hot stamping, pad printing

- 2K-production

- Mounting of assembly groups

- Overmolding of inserts

- Surface finishing of your products by electroplate, paint and steaming in cooperation with reliable partners

Injection moulding

We are producing in three shifts on 47 injection moulding machines with a mould clamping force of 25 t to 420 t. We process nearly all thermoplastics from standard plastics to high-strength plastics.

Design & mould making

We combine mould making with the injection moulding process and thus ensure that your product is optimally coordinated with the mould.

Our product developers, design engineers and mould makers combine state of the art technology with craftsmanship from the implementation of the drawing or the design draft up to the delivery of your mould so that your mould will become a masterpiece.

Products

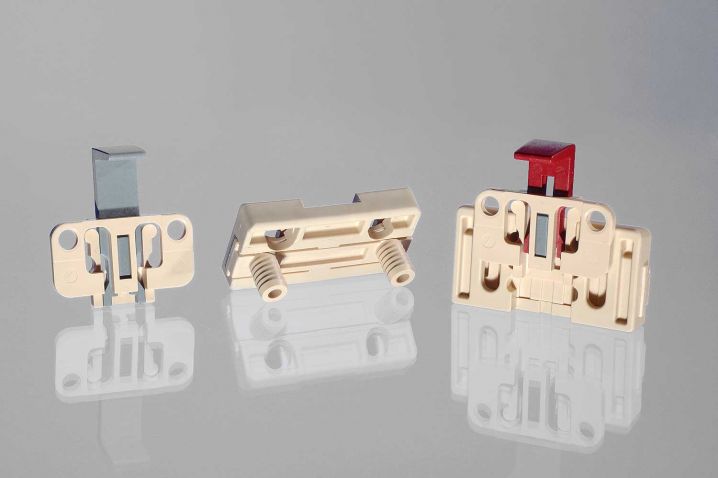

Our products

Jobs

Production staff (m/f)

Reliability, flexibility and readiness for shift working should characterise you.

A long-term cooperation with performance-linked wages are a matter of course.

Application documents

Please send your application documents to:

TKV Thermoform GmbH

Dirk Sabrautzki

Thiemsdorfer Straße 3

07381 Pößneck

Germany

or d.sabrautzki@tkv-thermoform.de

Contact

You can contact us personally or by phone

Monday - Thursday from 6:30 AM to 4:00 PM

Monday from 6:30 AM to 11:45 AM

TKV Thermoform GmbH

Thiemsdorfer Straße 3

07381 Pößneck

Germany

Tel +49 (0)3647 4399-0

Fax +49 (0)3647 4399-28

kontakt@tkv-thermoform.de

Direction

Imprint

TKV Thermoform GmbH

Kunststofftechnik und Formenbau

Thiemsdorfer Straße 3

Gewerbegebiet Pößneck-Ost

07381 Pößneck

Telefon: +49 (0)3647 4399-0

Telefax: +49 (0)3647 4399-28

Internet: www.tkv-thermoform.de

E-Mail: kontakt@tkv-thermoform.de

Managing director: Werner Siegert, Beate Hartmann